Views: 0 Author: Site Editor Publish Time: 2026-01-26 Origin: Site

Recently, SSAM achieved a key milestone in the “Factory Automation and Smart Warehouse Renovation Project” implemented for a leading South Korean battery materials company. The second batch of hardware equipment for the project has been shipped.

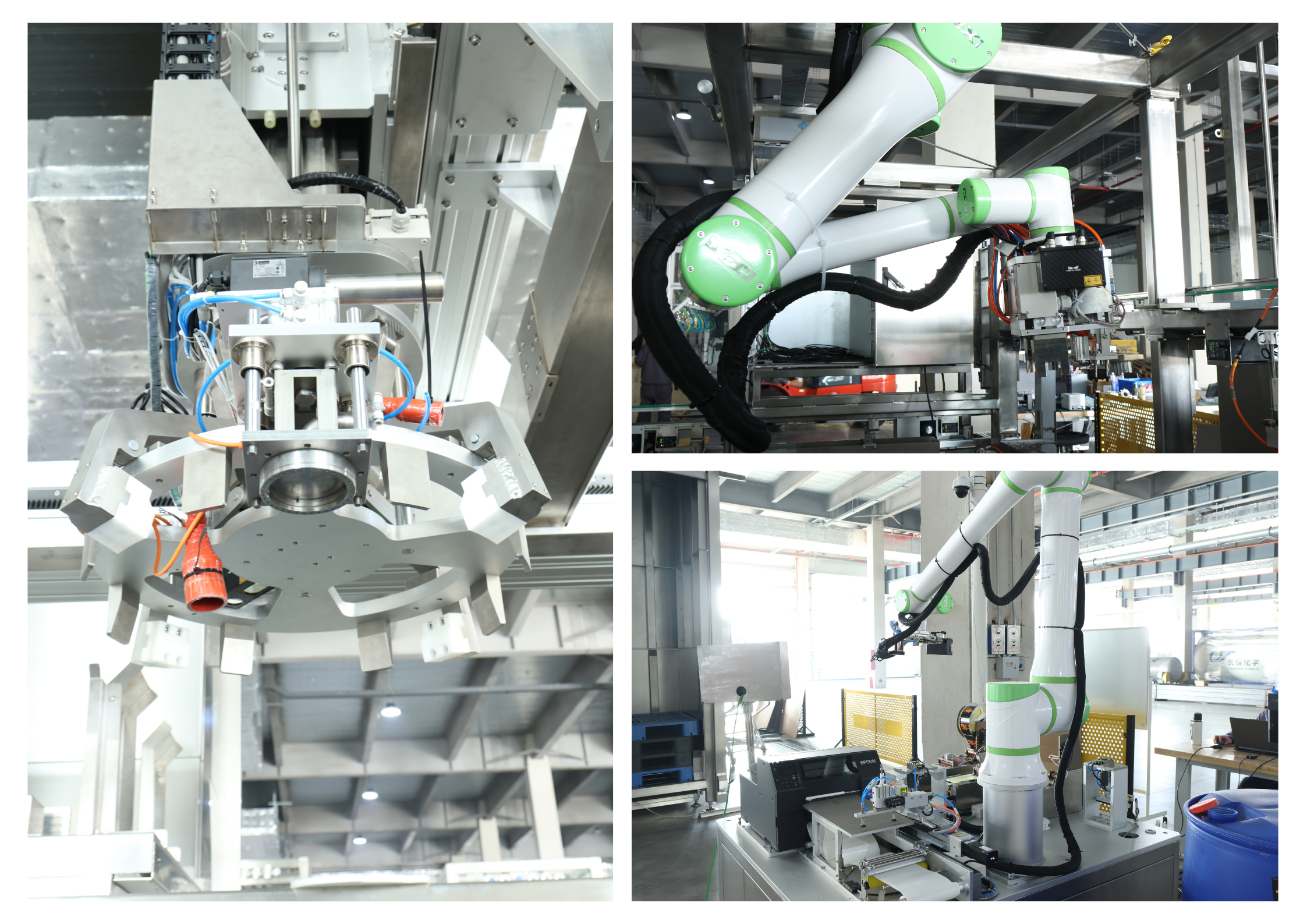

This delivery covers three core components: automated filling, powder packaging and feeding systems, and the smart warehousing system. The completion of the main hardware delivery marks a new stage in the project's implementation.

Centered around industrial robots, the project has created an efficient and precise, fully automated production line for the client, achieving production transparency and quality control. The system adopts a modular design, helping the client enhance efficiency, reduce operational costs, and build a high-efficiency, compliant, and scalable intelligent factory.

The first batch of hardware was delivered on early January , and this shipment represents the second batch. As planned, all software and hardware will be integrated, tested, and officially delivered for operation by Q1.

SSAM Smart Factory delivers an integrated, end-to-end service system covering design and R&D, intelligent manufacturing, and installation and delivery. We offer one-stop solutions including comprehensive smart factory planning, customized intelligent production lines, and the implementation of three-dimensional smart warehousing and logistics systems.

Moving forward, SSAM will continue to leverage its leading technology, quality, cost-effectiveness, and service to provide value-added services for new energy enterprises. Together with industry partners, SSAM will drive industrial progress and empower a new ecosystem for green manufacturing.